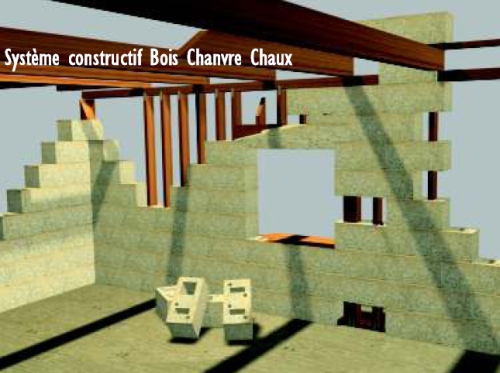

Geopolymer concrete block made with waste coal fly ash.

Project Type:

urban planning design strategy, architecture

Project Mission/Goal:

increase awareness of the environment and/or address climate change

Project Description:

The coal combustion process produces one of the largest unregulated solid wastes in the United States. Although in recent years a growing percentage of the airborne particulates (‘fly ash’) found uses as a filler in the cement industry, recent changes in EPA regulations aimed at reducing greenhouse gasses (GHG) emissions has resulted in most of the 70 million tons of fly ash produced annually in the US becoming unusable for current construction processes due to high levels of unburned carbon, ammonia and/or other impurities. Furthermore, the significant costs associated with transporting and land filling solids derived from coal combustion could be further increased due to liabilities associated with the eventual leaching of harmful levels of aluminum, chloride, iron, manganese and toxic levels of arsenic, nickel, lead, copper and zinc into subterranean water tables. Thus, the development of innovative technologies for converting tens of million tons of combustion bi-products annually into useful products is an urgent need.

What is Geopolymer:

-A hardened cementitious paste made from fly ash without Portland cement. It has greater compressive and tensile strengths, high strength gain rate, lower porosity and permeability, and greatly enhanced resistance to chemical attack compared with ordinary Portland cement (OPC) concrete. It combines waste products into a useful product, conserving landfill space and promoting sustainability, and compared with Portland cement, it features a 90% or greater reduction in carbon dioxide emission.

-A solution of sodium hydroxide and potassium hydroxide (waste products from the chemical and petrochemical industries) must be prepared separately, then added to the liquid commercial sodium silicate; this solution may then be added to the powdered fly ash (waste product from coal and bio fuel combustion) in the same way as water is added for Portland cement.

Source: Open Architecture Network

Read Full Post »